Highlights

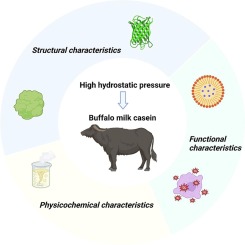

- •HHP altered buffalo milk casein’s tertiary structure.

- •The dispersion behavior of buffalo milk casein enhanced.

- •Foaming properties, oil-holding capacity, and emulsifying activity index improved.

- •Antioxidant activity and antibacterial effect against Escherichia coli increased.

Abstract

This study applied high hydrostatic pressure (HHP) treatment to buffalo milk casein to assess the influence of different pressure levels on its structural characteristics, physicochemical properties, and functional properties. The results showed that although HHP had no marked impact on the zeta potential and secondary structure, it altered the protein’s spatial structure (primarily its tertiary structure), and improved dispersion properties (such as particle size, solubility, and turbidity), as well as foaming properties. Additionally, HHP improved the antioxidant activity and antibacterial activity against Escherichia coli. However, HHP treatment negatively affected the water-holding capacity, emulsion stability, and antibacterial activity against Staphylococcus aureus. These findings suggest that HHP treatment is a potential method for modifying buffalo milk casein and provides a theoretical basis for its comprehensive utilization.

Introduction

Buffalo is an important and versatile livestock species, providing not only labor but also serving as a significant source of dairy and meat products (Luo et al., 2020). Globally, buffalo milk is the second-largest dairy resource after cow’s milk and is distinguished by higher levels of protein, fat, and total solids compared to cow’s milk (Rafiq et al., 2016). In terms of lactose content, buffalo milk (3.20–5.67 g/100 g) and cow milk (3.82–5.60 g/100 g) exhibit overlapping ranges (Abd El-Salam and El-Shibiny, 2011, Mejares et al., 2022). Similar to cow’s milk, buffalo caseins consist of αs1-casein, αs2-casein, β-casein, and κ-casein, each characterized by distinct amino acid compositions, genetic variations, and functional properties (Fan, Gao, Fu, Qiu, & Miao, 2020). In comparison to cow’s milk, buffalo milk contains lower concentrations of αs1-casein, while αs2-casein and β-casein are present at nearly double the concentration found in cow’s milk (Feligini, Bonizzi, Buffoni, Cosenza, & Ramunno, 2009). Additionally, buffalo milk casein micelles have lower hydration levels and contain more colloidal calcium and colloidal inorganic phosphate (Hussain, Bell, & Grandison, 2013). Currently, thermal processing is the primary method for treating buffalo milk in India, Pakistan, and Egypt. However, buffalo milk has poor thermal stability, with κ-casein being particularly susceptible to heat-induced dissociation from micelles, leading to coagulation (Deeth and Lewis, 2017, Huppertz, 2016, Khedkar et al., 2016). In contrast, non-thermal milk processing offers advantages such as preserving quality, achieving high microbial lethality at low temperatures, reducing energy consumption, and being environmentally friendly (Pegu & Arya, 2023).

High hydrostatic pressure (HHP) technology, an emerging non-thermal food processing method, achieves food safety levels comparable to thermal sterilization while inducing structural changes in proteins, thereby affecting their functionality and nutritional properties (Wang et al., 2022). Using water as a pressure transmission medium, HHP processes food materials at pressures ranging from 100 to 800 MPa (typically above 100 MPa), causing partial or complete disruption of macromolecular chains’ three-dimensional structures. This process alters protein structures or inactivates enzymes (Rivalain, Roquain, & Demazeau, 2010). HHP treatment has been shown to modify the tertiary structure of lactoferrin, enhance its digestive hydrolysis in the gastrointestinal tract, and increase the release of antioxidant-related amino acids and peptides (Guo et al., 2024). Kieserling et al. (2021) demonstrated that HHP induces structural changes in β-lactoglobulin, subsequently affecting its interfacial activity at oil/water interfaces. While HHP technology has been applied in buffalo milk processing (Huppertz et al., 2005, Yu et al., 2025), limited studies have explored its effects on buffalo casein.

This study aims to systematically investigate the effects of HHP treatment on the structural, physicochemical, and functional properties of buffalo casein. The findings will provide a scientific foundation and theoretical guidance for applying HHP in buffalo milk processing and casein modification within the food industry.

Materials

Five kilograms of fresh buffalo milk were purchased from a local buffalo farm in Foshan, Guangdong Province, China, and transported to the laboratory using cold-chain logistics.

Preparation of buffalo milk casein

Fresh buffalo milk was centrifuged at 4,000 × g for 30 min at 20 °C to remove the upper fat layer, resulting in skimmed buffalo milk. The pH of the skimmed milk was adjusted to 4.6, followed by incubation at 40 °C for 30 min to induce casein coagulation. The mixture was then centrifuged at 5,000 × g for 30 min at 4 °C,

Effects of HHP on the structure of buffalo casein

To evaluate the effects of HHP treatment on the secondary structure of casein, CD spectra were analyzed for samples subjected to various pressure levels. The CD spectra and corresponding changes in secondary structure are shown in Fig. 1A and B. Although the CD spectra curves exhibited slight variations, the secondary structure of casein was not significantly affected by the pressure treatments (P > 0.05).

To further examine the influence of HHP on the tertiary structure of casein, fluorescence

Discussion

The impact of HHP on the structure of buffalo casein was evaluated using CD spectroscopy, fluorescence spectroscopy, and surface hydrophobicity measurements. CD spectra analysis revealed that HHP treatment did not significantly alter the secondary structure of casein, aligning with the findings of Guo et al. (2024). Fluorescence spectroscopy was employed to monitor changes in the tertiary structure, while surface hydrophobicity assessments provided insights into the exposure of hydrophobic

Conclusion

Although HHP treatment did not affect the zeta potential and secondary structure of the protein, it altered the spatial conformation of buffalo casein, enhancing its dispersion behavior. As a result, the casein exhibited improved foaming properties, OHC, and EAI, while also enhancing its antioxidant activity and antibacterial activity against Escherichia coli. However, HHP treatment also had some negative effects, such as reducing WHC, ESI, and antibacterial activity against Staphylococcus.

Physicochemical Characteristics of Buffalo Milk Casein

- Higher Casein Content:

- Buffalo milk contains about 4.2–5.2% casein, which is higher than in cow milk.

- This contributes to its greater total protein and higher yield in dairy products (like cheese and paneer).

- Casein Types and Composition:

- Composed of αs1-, αs2-, β-, and κ-caseins.

- Buffalo milk typically has lower κ-casein and higher β-casein compared to cow milk.

- This affects micelle stability and rennet coagulation behavior.

- Micelle Size and Structure:

- Buffalo casein micelles are larger (average ~200–300 nm) than those in cow milk.

- Contains higher calcium and phosphate levels, which strengthen micelle structure and influence thermal stability.

- pH and Heat Stability:

- Higher buffering capacity due to more protein and mineral content.

- Casein in buffalo milk is less heat-stable at neutral pH compared to cow milk, due to micellar composition and mineral interactions.

Functional Characteristics of Buffalo Milk Casein

- Coagulation Properties:

- Excellent rennet coagulation, forming a firm curd — beneficial for cheese-making.

- Faster curd firming but slower gelation under acid conditions compared to cow milk.

- Water-Holding and Gelation Capacity:

- Greater water-holding capacity, making it ideal for yogurt, paneer, and dairy desserts.

- Forms firm and cohesive gels, due to higher protein content and micellar calcium.

- Emulsification and Foaming:

- Good emulsifying capacity due to amphiphilic casein molecules.

- Foaming ability is lower than cow milk casein due to higher fat and protein interactions.

- Digestibility and Nutritional Value:

- Slightly slower digestibility than cow milk due to denser protein networks.

- Rich in essential amino acids, making it nutritionally beneficial.