3 types of laying-hen houses, namely, high-rise (HR), manure-belt (MB), and cage-free floor-raised (FR), were monitored for air temperature, RH, CO2, and atmospheric NH3 under winter and summer conditions in Iowa. Under winter conditions, the HR and MB houses had more comfortable temperature and NH3 levels (mean 24.6 and 20.6°C, and maximum 9 to 24 ppm of NH3, respectively) than the FR houses (mean 15.5°C and maximum 85 to 89 ppm of NH3, respectively), and house temperature varied more with outside conditions. Under summer conditions, house temperature showed the least increase above ambient in the FR houses (mean 0.3°C vs. 4.7 and 1.2°C for the MB and HR houses, respectively), and NH3 levels were similar for all housing types (mean 3 to 9 ppm). Examination of the hen health status revealed differences in pathogen prevalence between housing systems for winter and summer, but not conclusively in favor of one system over another. Results of this study indicate that the benefits of each system were season dependent.

Further monitoring of the environment, bird health, and production performance over an extended period (e.g., 1 yr) to quantify the benefits and limitations of each system is warranted. Information of this nature will aid in optimizing hen housing systems for enhanced bird welfare and sustained production efficiency for the egg industry.

ammonia

temperature

Campylobacter

Salmonella

high-rise

manure belt

cage-free

DESCRIPTION OF PROBLEM

Bird welfare is an increasing issue of concern for the egg industry. Housing systems play a critical role in the welfare of laying hens, and various systems are implemented throughout the world. A segment of the US egg industry has begun modifying housing systems from conventional cages to alternative (noncaged) systems, although this trend is more prevalent in Europe. Behavioral benefits of cage-free systems are well documented, as are the disadvantages. Caged systems offer opportunities for better management and environmental control, reduced production costs, and more efficient use of resources. Important considerations for welfare also include environmental quality and hen health, but these parameters are not well documented for different laying-hen housing systems.

Different housing systems create unique management scenarios and can result in different housing environments for the same weather. Environmental temperatures not only influence hen comfort and performance, but also affect other environmental parameters, such as NH3 and dust levels in poultry houses . Ammonia emissions from layer houses have been shown to differ considerably among high-rise (HR), manure-belt (MB), and cage-free systems.

Bird welfare guidelines recommended by the United Egg Producers state that NH3 levels in chicken houses should ideally be less than 10 ppm and should not exceed 25 ppm. Studies have shown that laying hens find atmospheric NH3 highly aversive at concentrations of 25 ppm.Air quality for the humans working in poultry houses is also a concern. The National Institute for Occupational Safety and Health has established an 8-h time-weighted average limit of 25 ppm of NH3 for humans. The Occupational Safety and Health Administration has a permissible 8-h time-weighted average exposure limit of 50 ppm for humans.

Ample literature has documented the adverse effects of elevated atmospheric NH3 levels on poultry, such as reduced production performance and poor health of broilers reduced egg production, damaged respiratory tract, increased susceptibility to New castle virus , increased incidence of air sacculitis and keratoconjunctivitis (blind eye), and prevalence of mycoplasma galliseptium (MG). Egg quality may also be adversely affected by high levels of atmospheric NH3, as measured by reduced albumen height, elevated albumen pH, and albumen. To ensure good bird health and performance, it is recommended that atmospheric NH3 in poultry houses not exceed 25 ppm, which may be difficult to achieve in some housing types in cold weather. During summer (warm or hot weather), it may be difficult for houses with high numbers of birds to provide sufficient ventilation to maintain comfortable temperatures, even at the maximum ventilation rate.

The health state of the bird affects not only bird welfare, but also the microbial food safety of the consumer. Epedimolgical studies indicate that the prevalence of Salmonella or Campylobacter varies with housing system, diet, season, and age of the birds. A California study reported fewer Salmonella Enteritidis in caged birds (1.7%) than in free-range birds (50%), with a similar pattern for other group D Salmonella in caged (1.5 per 10,000) and free-range (14.9 per 10,000) hens. Likewise, significantly more Salmonella were isolated from floor pens than from batteries of caged laying hens. Salmonella prevalence in noncaged barns(61.5%) and free range (54%) exceeded that for caged systems (34%) in the United Kingdom. Similarly, among the multiple for Salmonella infection in laying hens of the same age, confining birds to a cage lowered the risk of Salmonella when compared with free-ranging hens. In contrast, others reported that Salmonella prevalence was highest in laying hens housed in conventional cage systems (46.3%) and was lowest in free-range flocks (21.9%). Still others reported no significant differences in Salmonella status when free-range vs. caged layers were evaluated. No studies have compared the prevalence of Campylobacter in layers maintained in different housing systems.

To fully assess the welfare of birds in a specific system, it is important to evaluate the system as a whole, including health, environment, behavior, handling and management practices, worker education and training, and economics. Few studies have compared air quality at the bird level in HR, MB, and cage-free littered floor-raised (FR) laying-hen facilities. Reports regarding hen health status and the prevalence of foodborne pathogens in these housing systems have been contradictory.

Therefore, the objective of this field was to characterize air quality and hen health status in 3 relatively common types of laying-hen housing—HR, MB, and FR—under both warm and cold climatic conditions in Iowa. These results may be useful for improving laying-hen husbandry and system operation.

MATERIALS AND METHODS

Description of the Laying-Hen Houses Monitored

Four houses in each hen-housing system (FR, HR, and MB) were selected for each monitoring period based on farm access and availability. The characteristics of the houses are described below and are summarized.

Table 1. Description of the laying hen houses monitored: floor-raised (FR)

| Season | Description | FR 1, site 1 | FR 2, site 1 | FR 3, site 2 | FR 4, site 3 |

|---|---|---|---|---|---|

| Ventilation | Natural | Mechanical, side inlets and fans | Natural, with chimneys | Natural | |

| Orientation | East-west | East-west | North-south | East-west | |

| Manure management | Litter, wood shavings added once at the start of the flock | Litter, wood shavings added once at the start of the flock, partial slatted floor with auger removal | Litter, sawdust added every 2 wk, partial slatted floor with auger removal | Litter, wood shavings added once at the start of the flock | |

| Winter 2006 | Date monitored | Jan. 10 to 11 | Jan. 10 to 11 | Jan. 10 to 11 | Jan. 10 to 11 |

| Bird age | 76 wk | 36 wk | 32 wk | 53 wk | |

| Flock size (initial) | 3,500 | 6,000 | 8,700 | 10,000 | |

| Summer 2006 | Date monitored | Aug. 7 to 8 | Aug. 7 to 8 | Aug. 7 to 8 | Aug. 7 to 8 |

| Bird age | 43 wk | 67 wk | 63 wk | 36 wk | |

| Flock size (initial) | 3,500 | 6,000 | 8,700 | 10,000 | |

| House dimensions | 40 × 160 ft; 12 × 49 m | 50 × 210 ft; 15 × 64 m | 40 × 300 ft; 12 × 91 m | 66 × 180 ft; 20 × 55 m | |

| Bird housing | Cage-free, free-range organic | Cage-free | Cage-free | Cage-free, n-3 diet | |

| Birds per group (W/S) | 3,500 | 6,000 | 8,700 | 10,000 | |

| Breed | Brown (U) | Brown (U) | Brown (U) | Brown (U) | |

| Space allowance, in/bird (W/S); cm/bird (W/S) | 263 + dpa; 1,698 + dpa | 252; 1,626 | 199; 1,284 | 171; 1,103 | |

| Water treatment | Peroxide | Peroxide | Peroxide | None, well water |

FR 1 to FR 4 refer to floor-raised houses 1 to 4.2

W/S = winter/summer.3

U = unknown, breed not documented.4

dpa = daily pasture access.

Table. Description of the laying hen houses monitored: manure-belt (MB)

| Season | Description | MB 1, site 4 | MB 2, site 4 | MB 3, site 4 | MB 4, site 4 | MB 5, site 4 |

|---|---|---|---|---|---|---|

| Ventilation | Mechanical, tunnel with lengthwise inlet | Mechanical, tunnel with lengthwise inlet | Mechanical, tunnel with lengthwise inlet | Mechanical, tunnel with lengthwise inlet | Mechanical, tunnel with lengthwise inlet | |

| Orientation | East-west | East-west | East-west | East-west | East-west | |

| Manure management | Removed daily | Removed daily | Removed daily | Removed daily | Removed daily | |

| Winter 2006 | Date monitored | Jan. 16 to 17 | Jan. 16 to 17 | Jan. 16 to 17 | Jan. 16 to 17 | DNM |

| Bird age | 39 wk | 98 wk | 45 wk | 109 wk | DNM | |

| Flock size (initial) | 104,500 | 106,400 | 106,400 | 93,200 | DNM | |

| Summer 2006 | Date monitored | DNM | DNM | Aug. 1 to 2 | Aug. 1 to 2 | Aug. 1 to 2 |

| Bird age | DNM | DNM | 76 wk | 32 wk | 50 wk | |

| Flock size (initial) | DNM | DNM | 106,400 | 106,400 | 106,400 | |

| House dimensions | 60 × 520 ft; 18 × 158 m | 60 × 520 ft; 18 × 158 m | 60 × 520 ft; 18 × 158 m | 60 × 520 ft; 18 × 158 m | 60 × 520 ft; 18 × 158 m | |

| Bird housing | Caged | Caged | Caged | Caged | Caged | |

| Birds per group (W/S) | 10 | 6 | 6 | 6 | 6 | |

| Breed | W-36 | W-36 | W-36 | W-36 | W-36 | |

| Space allowance, in/bird (W/S); cm/bird (W/S) | 54; 348 | 54; 348 | 54; 348 | 54; 348 | 54; 348 | |

| Water treatment | Ozonated | Ozonated | Ozonated | Ozonated | Ozonated |

MB 1 to MB 5 refer to manure-belt houses 1 to 5.2

DNM = did not monitor.3

W/S = winter/summer.

Table 3. Description of the laying hen houses monitored: high-rise (HR)

| Season | Description | HR 1, site 5 | HR 2, site 5 | HR 3, site 5 | HR 4, site 5 | HR 5, site 5 |

|---|---|---|---|---|---|---|

| Ventilation | Mechanical, ceiling inlet with side fans in manure storage area | Mechanical, ceiling inlet with side fans in manure storage area | Mechanical, ceiling inlet with side fans in manure storage area | Mechanical, ceiling inlet with side fans in manure storage area | Mechanical, ceiling inlet with side fans in manure storage area | |

| Orientation | East-west | East-west | East-west | East-west | East-west | |

| Manure management | Removed between flocks | Removed between flocks | Removed between flocks | Removed between flocks | Removed between flocks | |

| Winter 2006 | Date monitored | Jan 21 to 22 | Jan 21 to 22 | Jan 21 to 22 | Jan 21 to 22 | DNM |

| Bird age | 42 wk | 46 wk | 93 wk | 142 wk | DNM | |

| Flock size (initial) | 66,061 | 65,141 | 64,727 | 80,174 | DNM | |

| Summer 2006 | Date monitored | DNM | Jul 24 to 25 | Jul 24 to 25 | Jul 24 to 25 | Jul 24 to 25 |

| Bird age | DNM | 99 wk | 22 wk | 72 wk | 39 wk | |

| Flock size (initial) | DNM | 65,141 | 63,006 | 73,600 | 66,061 | |

| House dimensions | 48 × 430 ft; 15 × 131 m | 48 × 430 ft; 15 × 131 m | 48 × 430 ft; 15 × 131 m | 48 × 430 ft; 15 × 131 m | 48 × 430 ft; 15 × 131 m | |

| Bird housing | Caged | Caged | Caged | Caged | Caged | |

| Birds per group (W/S) | 8 | 8 | 9/8 | 6/5 | 8 | |

| Breed | W-36 | W-36 | W-36 | W-36 | W-36 | |

| Space allowance, in/bird (W/S); cm/bird (W/S) | 59; 381 | 59; 381 | 56/61; 361/394 | 56/61; 361/394 | 59; 381 | |

| Water treatment | None | None | None | None | None |

HR 1 to HR 5 refer to high-rise houses 1 to 5.2

DNM = did not monitor.3

The 4 FR houses were located on 3 separate sites (sites 1, 2, and 3) within 16 km (10 mile) of one another, featuring partially or fully littered floors; automated feeding, watering, and egg collection; and nest boxes. One house was used to produce organic eggs, in which hens were allowed access to outdoor pasture under suitable weather. Two houses had a partially slatted floor located along the center of the house, and manure that accumulated beneath the slatted floor was removed several times per year. Three houses were naturally ventilated, whereas the fourth one was mechanically ventilated. Three houses had an east-west orientation, and one of the naturally ventilated houses had a north-south orientation. The same FR houses were monitored for both summer and winter conditions.

The sets of MB and HR houses monitored were each located at a commercial egg-production site (sites 4 and 5, respectively. Manure was removed daily from the MB houses, whereas it was scraped from the dropping boards into the lower-level storage area 4 times daily in the HR houses, and the stored manure was cleaned out once a year (generally in the fall). Two of the same MB houses were monitored for both summer and winter conditions; the additional houses monitored were not the same for each monitoring period. For summer conditions, only 3 MB houses were available during summer because of an unexpected event. Three of the same HR houses were monitored for both summer and winter conditions; the fourth house monitored was not the same for each monitoring period.

Monitoring of Environmental Conditions

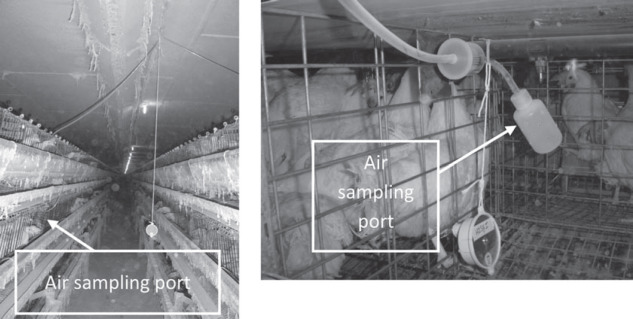

Environmental variables measured near the bird level included NH3, CO2, air temperature, and RH. Each house was monitored continuously over a 20- to 24-h period in winter and summer. All 12 houses in the study contained adult laying hens of various ages, but hens within a house were of the same age. Ammonia and CO2 concentrations inside the barns were measured at 30-min intervals by using portable monitoring units previously developed for monitoring poultry building NH3 and CO2 emissions. A 3-location composite air sample across the width of the house and nearly one-third into the length of the house was taken for the air sampling. Air temperature and RH inside and outside the barns were recorded at 5-min intervals by using programmable, portable air temperature/RH (T/RH) loggers. One T/RH logger was placed at each sampling port. For caged houses, an additional T/RH logger was placed in the cage aisle near each sampling port (approximately 1.5 m, or 5 ft, distance from the logger inside the cage).

Examination of Hen Health Status

Ten birds were randomly selected from each house on the day of monitoring for assessment of health status, tracheal condition, and prevalence of Campylobacter and Salmonella. For winter sampling, a total of 40 noncaged and 79 caged (n = 40 MB and n = 39 HR) hens were examined. For the summer, noncaged birds (total of 40) and caged birds (total of 70: n = 30 for HR, and n = 40 for MB) were assayed. Blood samples were taken from each hen, and sera from these samples were subsequently tested for the presence of antibodies against MG and mycoplasma synovia(MS) by the serum plate agglutination test. Birds were killed via injection of sodium pentobarbital, and trachea, small intestine, and ceca samples were collected.

For more information……

Tracheal Analysis.

Tracheas were fixed in 10% neutral buffered formalin, dehydrated in a graded series of ethanol, and embedded in paraffin. Sections were cut (4 μm in thickness) and stained with hematoxylin and eosin for examination by light microscope.

Intestinal Homogenates.

Ceca and small intestine were collected and refrigerated (4°C). A 10% (wt/vol) homogenate was prepared in buffered pepton water as described previously.

Detection and Identification of Campylobacter spp. and Salmonella.

For identification of Campylobacter, presumptive Campylobacter isolates were confirmed and speciated as compylobacter coli or compylobacter jejuni by PCR as described previously. For identification of Salmonella, the buffered peptone water homogenate (10% wt/vol) was incubated (24 h, 37°C) aerobically. After incubation, 1 mL of the enrichment was transferred to 10 mL Hajna broth and incubated (24 h, 42°C) aerobically.

Data Analysis and Presentation

For environmental conditions, data were summarized for each house and combined into mean plots for each variable during each monitoring period. To describe the combined effects of air temperature and RH under warm conditions, the temperature-humidity index (THI) for laying hens was calculated using the relationship THI = 0.6Tdb+0.4Twb, where Tdb = dry-bulb temperature and Twb = wet-bulb temperature. Daily mean environmental conditions were each compared for housing type, and differences were determined by least square means. For the health status data, 2-factor repeated measures analyses were used in 2 different comparisons between winter and summer prevalence of Campylobacter and Salmonella.

The first comparison examined differences among birds under the 3 housing schemes (noncaged FR, caged HR, and caged MB) over 2 trials (winter and summer) using 4 replicates. The second comparison examined differences between caged and non caged birds over winter and summer with an unequal number of replicates. Differences were considered statistically significant at P < 0.05.

RESULTS AND DISCUSSION

Bird-Level Environmental Conditions

Environmental conditions differed for all 3 housing types. There was greater variability among the FR houses, which were independently operated, with different housing configurations and flock management practices. Variability was less for houses located on the same site and operated under the same management, as was the case for the MB and HR houses. House ventilation system differed, which would explain some of the observed variations in environmental conditions. Additionally, the FR houses had only 1 level of birds, with 3 to 5 times more space per bird than the HR or MB houses, resulting in much less heat production as well as lower CO2 concentrations. Interestingly, conditions were the most similar for houses FR 1 and FR 2, located on the same site with the same management personnel, although 1 house was naturally ventilated and the other was mechanically ventilated.

Winter.

The 24-h mean, maximum, and minimum values of each variable for each housing system in winter are summarized in and depicted in. Temperatures and NH3 levels were within comfortable or recommended ranges throughout the monitoring period for the HR and MB houses. In comparison, NH3 concentrations in the FR houses substantially exceeded the recommended level of 25 ppm, with a daily mean of 46 ppm, as compared with 14 ppm for the HR houses and 7 ppm for the MB houses. The maximum concentration in the FR houses reached 85 to 89 ppm. Temperatures in the FR houses tended to fluctuate with the outside conditions. The bird-level temperature was considerably cooler in the FR houses than in the HR or MB houses, averaging 15.5 ± 1.5°C vs. 20.6 ± 0.8°C for the HR houses and 24.6 ± 1.0°C for the MB houses. Compared with the HR or MB houses, the smaller number of hens per unit space, and thus lower heat production, in the FR houses was the primary reason for their cooler temperature. The lower metabolic heat production in the FR houses corresponded to lower CO2 concentrations (mean ± SE), 2,021 ± 199 ppm for FR, as compared with 2,433 ± 95 ppm for HR and 3,072 ± 36 ppm for MB. Frequent (daily, in this case) removal of manure from the MB houses greatly reduced NH3 concentrations.

CONCLUSIONS AND APPLICATIONS

- 1.Differences in environmental conditions and pathogen frequency were observed among all 3 housing types during summer and winter conditions. During winter, NH3 levels were much higher in the FR houses (46 ± 9 ppm) than in the HR (14 ± 3 ppm) or MB (7 ± 0 ppm) houses. Air temperature in the FR houses also fluctuated more, following the outside temperature. Some of the air quality issues observed may be improved with management (periodic addition of fresh bedding), ventilation adjustments (e.g., use of minimum ventilation fan in cold weather), or both.

- 2.Pathogen prevalence varied within housing system for winter and summer. Producers should be aware and take proactive management measures during the seasons with higher prevalence for their respective housing type.

- 3.Assessment of each housing system as a whole made it unrealistic to discern the specific sources of benefits or limitations associated with each system. Nevertheless, results from 2 of the FR houses (FR 1 and FR 2) suggest that management likely plays a greater role in environmental conditions than housing type or ventilation type.

- 4.Differences observed in the air quality and the seasonal pathogen frequency merit further research to quantify and identify sources and mechanisms of these differences.

- 5.To better represent and control the bird-level microenvironment, it may be prudent to monitor the cage interior temperature periodically and adjust the temperature set point accordingly. Alternatively, one can consider locating the thermostat temperature sensors near the bird microenvironment, for example, by placing sensors in empty cages next to occupied cages.

Air quality and bird health status in three types of commercial egg layer houses In this blog, we cover everything you need to know to respond quickly and confidently when your dog has diarrhea. For further questions or professional guidance, feel free to contact us at

1. What are the three types of commercial egg layer houses compared in the study?

Answer:

The three types of egg layer housing systems typically compared are:

- Conventional cage (CC) systems

- Enriched colony cage (ECC) systems

- Aviary (AV) or cage-free systems

These systems differ in space, ventilation, and manure management—all of which influence air quality and bird health.

2. How does air quality vary among the three housing systems?

Answer:

- Ammonia (NH₃) levels are usually highest in aviary systems, due to manure being stored under slatted floors with less frequent removal.

- Dust levels tend to be higher in aviaries because of greater bird movement and litter.

- Cage systems (both conventional and enriched) generally show better air quality due to automated manure belts and better ventilation.

3. How do these air quality differences impact bird health?

Answer:

Poor air quality, especially high ammonia and dust levels, can lead to:

- Respiratory issues (e.g., tracheal inflammation)

- Eye irritation

- Reduced immune function

- Higher incidence of infections

Birds in aviary systems often experience more health issues related to air quality compared to those in enriched or conventional cages.

4. What management strategies can improve air quality in all systems?

Answer:

- Frequent manure removal (e.g., via belt systems)

- Adequate ventilation and air circulation

- Litter management in cage-free systems to reduce moisture and dust

- Use of air scrubbers or biofilters to reduce ammonia and particulates

These strategies help maintain healthier environments regardless of housing type.

Greetings,

Unlock a new phase of growth with Shrooq Loan dept funding opportunities, as we ensure you have a reliable business partner to secure your funding. Do you have project that is in need of financial growth, such as Working Capital or Start ups.

Here is your opportunity to secure your Seed Capital, Early-Stage, Renewable Energy Project, Commercial Real Estate, Telecommunication, Infrastructure, Agriculture, Animal Breeding, Healthcare, and Oil/Gas/Refinery. Competitive interest rates, Easy and fast reliable application process.

Your quick response, will enable further communication to commence.

Regards

Garth Daniels

Investment Representative

Shrooq AlQamar Project Management Services Co LLC

WhatsApp – +97333872035

Email: agent@shrooqconsultant.com

Our Offices: UAE Facilitating Office: Ahmad Al Jaber St

Oman Branch Offices: CHXM+J3G, Sohar, Oman

UAE Dubai: Financial Consortium